All the three Dryers are of the Rotary type, having inclined indirectly heated surfaces. They are, however,

suitable for only free flowing materials, which are readily converted from slurry or wet cake to free flowing

powder without exhibiting sticking or lump forming properties during the course of drying operations.

Application data

- These Dryers are used for free flowing, temperature sensitive materials.

- These Dryers are also used for drying expensive pharma materials where high degree of purity is required.

They can be provided with specially designed choppers with mechanical seals for de-lumping the powders

during drying.

- Nitrogen blanketing can be provided by way of seals at charging and discharging points, for drying

of highly explosive materials.

Special Configuration

RCVD'S with Chopper Design. For deagglomeration of powders which tend to form lump during the tumbling action

of the dryer. Deagglomeration would facilitate complete drying of the product and prevent lump formation.

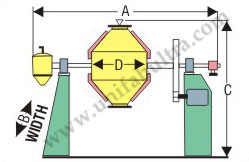

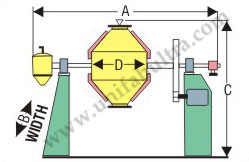

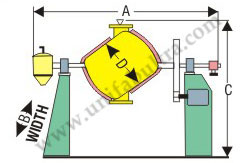

Rotocone Dryer

| Nominal Volume |

Charging Capacity |

RPM |

Power H.P. |

Space requirement |

Dia. D |

| A |

B |

C |

| 1000 |

400 |

1.5 - 6 |

3.0 |

3650 |

2000 |

2000 |

1300 |

| 1500 |

600 |

1.5 - 6 |

3.0 |

3880 |

2400 |

2600 |

1500 |

| 2500 |

1000 |

1 - 4 |

5.0 |

4300 |

2700 |

2800 |

1650 |

| 4000 |

1600 |

1 - 4 |

5.0 |

4650 |

3100 |

3100 |

2000 |

| 6000 |

2400 |

1 - 3 |

7.5 |

5000 |

3700 |

3700 |

2250 |

| 8000 |

3200 |

1 - 2 |

10.0 |

5600 |

4200 |

4200 |

2500 |

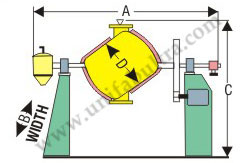

Thumbling Dryer

| Nominal Volume |

Charging Capacity |

RPM |

Power H.P. |

Space requirement |

Dia. D |

| A |

B |

C |

| 100 |

40 |

3 - 12 |

0.5 |

2450 |

1000 |

1600 |

500 |

| 300 |

120 |

3 - 12 |

0.5 |

2680 |

1250 |

1900 |

750 |

| 500 |

200 |

1.5 - 6 |

1.0 |

3100 |

1500 |

2200 |

900 |

| 1000 |

400 |

1.5 - 6 |

3.0 |

3700 |

1900 |

2350 |

1100 |

| 1500 |

600 |

1.5 - 6 |

5.0 |

3900 |

2100 |

2500 |

1200 |

| 2500 |

1000 |

1 - 4 |

5.0 |

4300 |

2600 |

3000 |

1500 |

| 4000 |

1600 |

1 - 4 |

5.0 |

5100 |

3100 |

3200 |

1700 |

| 6000 |

2400 |

0.75 - 3 |

7.5 |

5300 |

3500 |

3700 |

1900 |

| 8000 |

3200 |

0.75 - 3 |

10.0 |

5700 |

3700 |

3900 |

2100 |

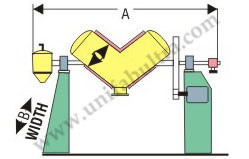

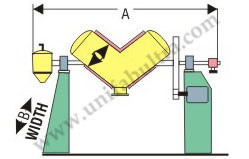

V-Type Dryer

| Nominal Volume |

Charging Capacity |

RPM |

Power H.P. |

Space requirement |

Dia. D |

| A |

B |

C |

| 100 |

40 |

3 - 12 |

0.5 |

2400 |

1200 |

1600 |

420 |

| 300 |

120 |

3 - 12 |

0.5 |

2600 |

1500 |

2200 |

635 |

| 500 |

200 |

1.5 - 6 |

1.0 |

3200 |

1600 |

2400 |

760 |

| 1000 |

400 |

1.5 - 6 |

3.0 |

4200 |

2200 |

2800 |

1000 |

| 1500 |

600 |

1.5 - 6 |

5.0 |

4700 |

2300 |

3200 |

1100 |

| 2500 |

1000 |

1 - 4 |

5.0 |

5400 |

2700 |

3700 |

1400 |

| 4000 |

1600 |

1 - 4 |

5.0 |

5660 |

2800 |

4100 |

1500 |

| 5400 |

2160 |

1 - 3 |

7.5 |

6400 |

3200 |

5200 |

1600 |